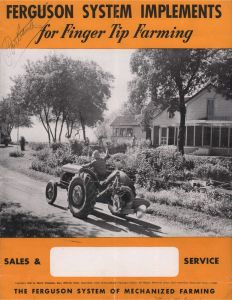

Delivery of First Ford Ferguson Tractor to the Northwest in 1939 by airfreight

(Wade Newbegin seated on tractor, Ernie Crichton on right)

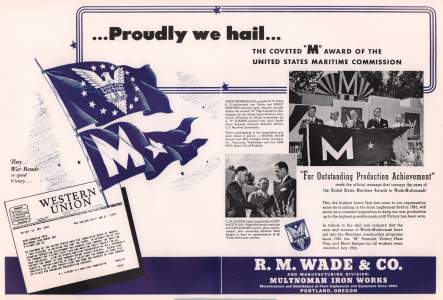

This was one of the most interesting and prosperous eras for the company beginning with the introduction of the famous Ford Ferguson tractor to the Northwest in 1939. The new hydraulic system of this tractor enabled the tractor and implement to act as a single machine and became the design standard for tractors for the future. During the World War II, the factory made equipment for use on army tugs and components for aircraft carriers which were made in the Kaiser Shipyards in Vancouver. It was awarded the prestigious “M” Maritime Award for outstanding contribution to the war effort. In 1949 the Ford Tractor line was replaced with New Holland balers and hay equipment. The sales of Goulds pumps increased for the industrial and water system markets. Wade Rain invented Poweroll, its first wheel line type product, and the distribution division introduced rotary tillage to the Northwest with the Howard Rotavator.

Percentage of Labor Force in Farming in 1950 – 8.3%

1939

The Tractor That Revolutionized Farming

1939-1940

In 1939 Wade Newbegin was invited to a meeting in Dearborn Michigan for the introduction of the Ford-Ferguson tractor. Harry Ferguson an inventor from England had designed a new tractor and it was so innovative that Henry Ford made a handshake agreement with him to make the tractor in the United States. This tractor was so advanced that nobody believed it would perform as claimed. At a meeting in Dearborn Henry Ford showed off the new tractor to prospective distributors as well as the press.

The video below shows Harry Ferguson being interviewed next to the tractor. It is believed that it is Edsel Ford that is sitting on the tractor. This video is an ad for the new tractor and it explains its advantages. The selling price was $578 (It says $675 in the picture below) to the farmer and it was the first modern tractor which incorporated the features of all tractors made today. The genius of the Ford-Ferguson tractor was that it made the tractor and the implement one machine. It did this by incorporating a hydraulic system into the tractor. It was used to connect implements (plows, cultivators, balers etc.) to the tractor and (the implement?) could be raised and lowered by hydraulic power. In addition the tractor had a (PTO What is this?) shaft in the rear which was used to power the implement behind the tractor. See the tractor ad for a demonstration of these features. R.M Wade sold thousands of these tractors every year and it was the most popular tractor sold in the United States. For the full story of RM Wade and the Ford Tractor read the PDF of Chapter 5 of Wade Newbegin's book.

1941

Pearl Harbor Attack United States Enters World War II

War Production Board and 24/7 Manufacturing

With the advent of World War II all manufacturing plants switched to manufacturing items for the war effort. At the age of only thirty-three years, Wade Newbegin was appointed to the prestigious National War Production Board. He served on the food production committee which was responsible for allocating all farm machinery production during World War II. Feeding both the domestic population and American soldiers was one of the highest priorities for the country. Farm equipment was necessary to accomplish this task. There was an allocation of farm equipment for each area of the country and each dealer was allowed a certain number of tractors to sell. The demand for equipment was so high that tractors were snapped up as soon as they arrived at the dealership.

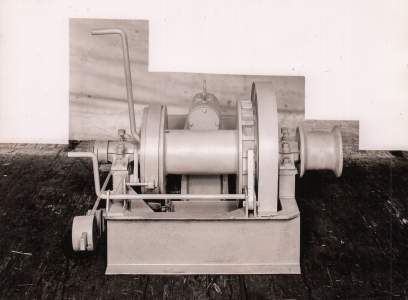

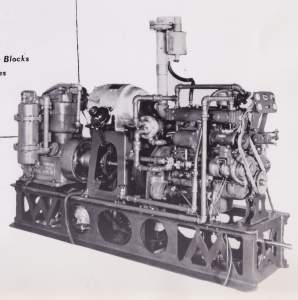

Multnomah Iron Works (later Wade Manufacturing Company) ran twenty-four hours a day seven days a week to make products for the war effort. The company made an auxiliary power unit for army tugs that provided compressed air, electricity, and pumping all in one machine. It was designed by Ray Letson, service manager of R.M. Wade and it was a big success. Another product he designed was a gasoline powered winch. Nothing like it had ever been made before and the company made thousands of these units. In addition degassing pumps for the BB-3 aircraft carriers were manufactured. The giant Kaiser Shipyards were located close by in Vancouver, Washington and many parts of the liberty ships made there were sub-contracted to the company. During the war there was a 90% excess profits tax on all profits made by the company.

1944

R.M. Wade Awarded Prestigeous 'M' Award

In 1944 the company received a telegram that it had been chosen for the "M" Award by the United States Maritime Commission. This was one of the highest civilian awards for contribution to the war effort. Nationally, only 175 of these awards were given to manufacturers and 35 to shipyards.

1945

Return to A Peacetime Economy

Post War Period

R.M. Wade & Co. flourished during the era following World War II. The company had many product lines that it was distributing and manufacturing and each type of product was sold by a specialized sales division dedicated to that product. Following the war these divisions were Farm Equipment, Water Systems, Industrial Pumps, Wade’Rain Pacific Northwest, Wade Rain National and International, Home Appliances, and Poultry Sales. The Tractor Sales Division which sold Ford Tractors and Goulds Pumps Western were separate corporations and sales organizations. Tink Smith was General Sales Manager with a Division Sales Manager reporting to him; Ernest Crichton was the Ford-Ferguson tractor Sales Manager.

1949

RM Wade Resigns as Ford Tractor Distributor

Dealers wanted to carry both the implements from R.M. Wade & Co. and the Ford tractor sold by the Tractor Sales Company. This created a lot of conflict between dealers and also within the company as everyone wanted to sell the popular Ford tractor. Furthermore Ford wanted R.M. Wade & Co. to carry Ford made implements rather than the products made by independent companies. Wade Newbegin decided that to do so would give Ford too much control over R.M. Wade & Co. Consequently, in 1949 he advised Ford that the company was resigning as their tractor distributor. He cooperated with Ford in the appointment of a new distributor. R.M. Wade & Co. was the only company ever to resign voluntarily as a Ford Tractor distributor. Immediately following the change, R.M. Wade became the Northwest distributor for the New Holland Machinery Company, the leading manufacturer of hay balers and other hay related machinery such as mowers and rakes.

1950

Pumps West

Goulds Pump Western, Inc.(later called Pumps West) was established for the sales of Goulds Pumps in the Northwest. R.M. Wade & Co. was both a distributor and an agent for Goulds. Most of the sales were to the pulp and paper mills and water pumps to municipalities. Also the company assembled pumps at Wade Mfg Co to give faster delivery to the customers. Eventually Pumps West became a substantial company in its own right and was bought out by Goulds Pumps when they started selling direct into the territory.

Wade Rain Introduces Patented Self Draining Gasket

"The Gasket that Thinks"

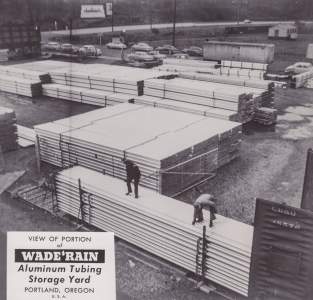

Several innovations in 1950 established Wade Rain as the leader in handmove coupler irrigation design. First, the company changed the coupler from steel to aluminum which meant the it would last virtually forever as compared to steel which eventually rusted out. Second, and more importantly Wade introduced the new single edge gasket which was not only the fastest draining but also drained the most sand and debris from the irrigation line. Previously sand accumulated around the gasket and prevented it from draining. The gasket was invented by Wade Rain engineer, Gail Cornelius. It was called the "gasket that thinks" because it knew to drain the water and debris from the line.

1951

New Holland Balers

1950-1963

The New Holland line of hay balers and equipment became the major agricultural implement line distributed by R.M. Wade. Within a year of cancelling Ford, the lost Ford sales were replaced by New Holland sales. It was a time of rapid progress and mechanization of the hay handling process. The major product sold in the New Holland line was the baler. It was by far the best baler on the market. New Holland took over direct sale to dealers in the Northwest in 1963. At the time R.M. Wade New Holland sales were $3.5 million or $26.5 million in today's dollars.

Shown in the video below is the New Holland Model 280, a very popular and In addition there is a video of typical New Holland baler. In addition there is a video of the automatic hay wagon, which was the first machine ever developed to automatically pick up hay bales and stack them.It was invented in California and named the Harobed, the backward spelling of Deborah, the wife of the inventor. Anyone who has ever "bucked hay" knows this invention brought a welcome change and relief from backbreaking work.

1952

IDC Appointed as Exclusive Export Agent for Wade Rain

In 1952 Wade Rain appointed IDC (Irrigation Development Corporation) as its exclusive distributor for international markets. This company was very successful in selling Wade Rain around the world and establishing Wade Rain as an international brand in irrigation. Some of the largest sales were in Brazil for coffee production and Guatemala for sugar. IDC was owned by Ronald Gilbert, who later named it Irridelco. In 1979 the exclusive contract with Irridelco was cancelled as Wade Rain moved to direct sales to the international market. Even today some of the Wade Rain international customers were originally established by IDC in the 50's.

The R.M. Wade Foundation was Created Honoring Robert M. Wade

In 1952 the R.M. Wade Foundation was established. This foundation gives scholarships to students, who are studying the agricultural sciences, at Oregon State University, Washington State University and the University of Idaho. The R.M. Wade Foundation also gives annual Excellence in Teaching Awards to agricultural professors in the same universities. Since its establishment in 1952 the foundation has given over 400 scholarships and teaching awards in honor of Robert M. Wade. See the following link for more information regarding the R.M. Wade Foundation. The foundation qualifies as a 5013c charitable organization and all contributions are tax deductible. All foundation administrative costs are paid for by the company.

R.M. Wade Move to NW Thurman St.

In 1952 R.M. Wade & Co. relocated to Thurman Street in Northwest Portland, where the company had purchased land and built a more spacious building. The new building was occupied until 1972, when it was displaced by the construction of the new Fremont Bridge.

1953

Howard Rotavator

A Major Innovation in Tillage Equipment

The traditional practice of farming prior to the Howard Rotavator was to plow the field first, then to use a disc or harrow to break up the clods of dirt, and then to employ other equipment to smooth out the soil in preparation for planting. The Howard Rotavator was the first machine to completely prepare the soil for planting with one pass of the tractor. This saved a lot of time and money for the farmer and actually made a better seed bed for planting. It was invented in Australia by Arthur Clifford in 1912 and patented in 1922. The innovative concept was of a machine with a rotary shaft, powered by the tractor through a gear box and an "L" shaped blade welded to the shaft, which rotated at high speed breaking up the soil effectively and rapidly. Sales were so strong in Australia that a company, called The Rotary Hoe Company, was established in England. Later the company was renamed Howard Rotavator, which became one of the most successful farm equipment companies in England. It manufactured and sold products throughout the world. The Howard line was distributed by R.M. Wade & Co. from 1953 to 2008 and was one of the most successful products ever sold by the company.

1954

First Wade Rain Poweroll Sold

In the 50's there was increased demand for the automation of hand move irrigation systems. Moving pipe was hard work and labor was becoming short on the farm. The use of aluminum pipe, much lighter than the steel used previously in hand move irrigation systems, allowed for advances. Wade Rain started experimenting with sideroll type irrigation. Sideroll is a long sprinkler line on wheels driven by a mover unit in the center of the line, which rotates the pipe as a single axle, thus driving the entire line forward for the length of the field. Gail Cornelius, a Wade Rain engineer, designed a side roll type irrigation system called Wade Rain Poweroll. Although today it looks like a simple machine, it took many years to perfect it. There were major problems to overcome, such as draining the line before it was moved. Many attempts were made to design a valve which would reliably and automatically drain the line. If it was not drained before the line was moved, the weight of the water would break the pipe. Gail Cornelius came up with an entirely new valve which was very successful in automatically draining the pipe. It was patented and made the Wade Rain Poweroll superior to all other sideroll systems.

Below is a picture of Gail Cornelius, who designed and patented the Wade Rain Poweroll irrigation system, as well as many improvements.

1955

Farm Show

R.M. Wade & Co. participated in many agricultural shows over the years. This picture was probably taken at the Oregon State Fair sometime in the 50's. Farm show displays were a good way to reach customers.

Multnomah Iron Works Flooded

Multnomah Iron Works/ Wade Manufacturing Company was located in the Guilds Lake Area of Northwest Portland. Previously it had been a lake and was the setting for the Lewis and Clark Exposition in 1904. After the Exposition the lake was filled in and industries were encouraged to locate there. Periodically over the years the area flooded and became a lake once again due to rainwater runoff from the West Hills. The worst flood was in 1969 when the flood water was so high it almost caused the Wade Foundry furnaces to explode. It rose within two inches of the top edge of the furnace containers, which held molten metal. The molten metal was at 900 degrees and contact with the water would have caused an explosion. It was a lucky day. The rainwater began to recede before the furnaces were flooded.

1958

David Brown Tractors

In 1958 R.M. Wade made an agreement to distribute David Brown tractors in the United States. David Brown was an English company that had been established in 1860. Originally it made gear drives and by 1920 it was the largest manufacturer of worm gears in the world. Most of the ships in the British navy were driven by David Brown gears. In 1936 the company entered into a joint venture with Harry Ferguson and produced the Brown-Ferguson tractor, three years before Ford started building the same tractor in 1939. R.M. Wade had great success with the David Brown tractor for over ten years. However, in 1972 the company had financial difficulties and was forced to sell the tractor line to J.I. Case, who immediately cancelled all of the independent distributors.

David Brown is best known as the manufacturer of the Aston Martin, the famous high performance car used in the James Bond movies.

1960

Multnomah Iron Works name changed to Wade MFG Co

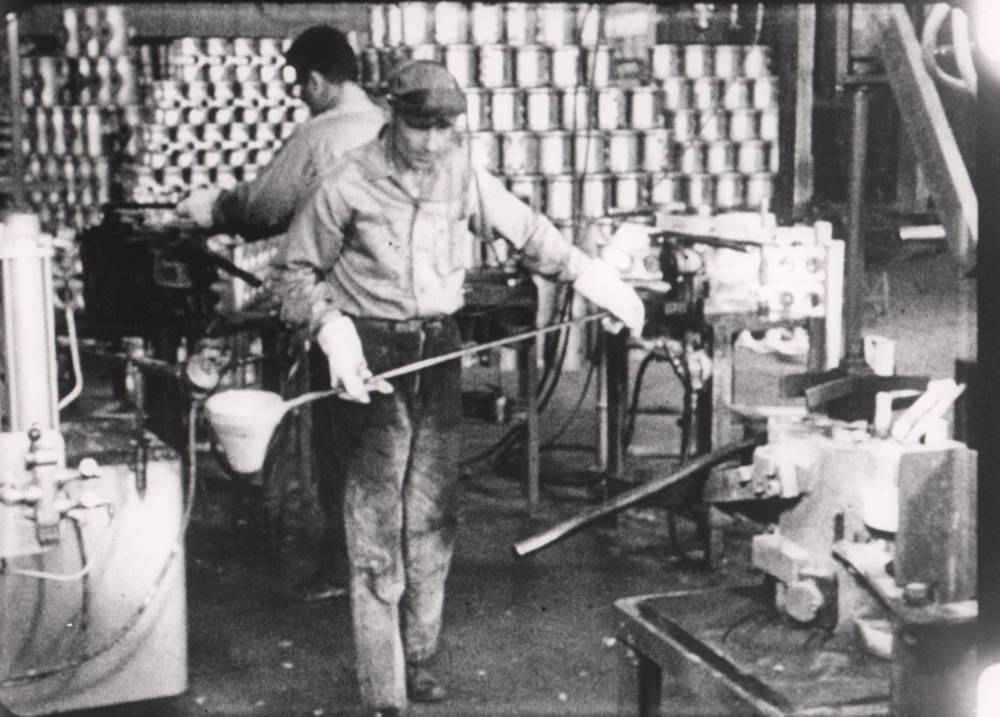

Picture Taken of Wade Mfg. Co Around 1960

1961

Importing Started

Only sixteen years after the end of World War II, R.M. Wade & C0. started importing baling wire and roller chain from Japan, through another subsidiary called U.S. Imports. Most of the products were imported from Sumitomo Corporation one of the largest companies in Japan.

1962

Foundry Operation Added to Wade MFG CO.

Originally Alcoa had made the castings for the couplers designed by Wade Rain. However, in 1962 Alcoa discontinued production of castings and Wade Manufacturing opened a foundry to make their own castings. Ed Mason came to Wade from Alcoa to be the superintendent of the new foundry operation. He did an excellent job of leading the foundry for the next twenty years, until his retirement in the 80's. The new foundry was able to produce a very high quality product by using a special high-strength alloy designed for Wade by Alcoa. This additional strength proved to be an important improvement as couplers were always banged around a lot when farmers moved and stacked pipe.

In one year alone, the Wade Manufacturing foundry poured over a million pounds of aluminum.

1964

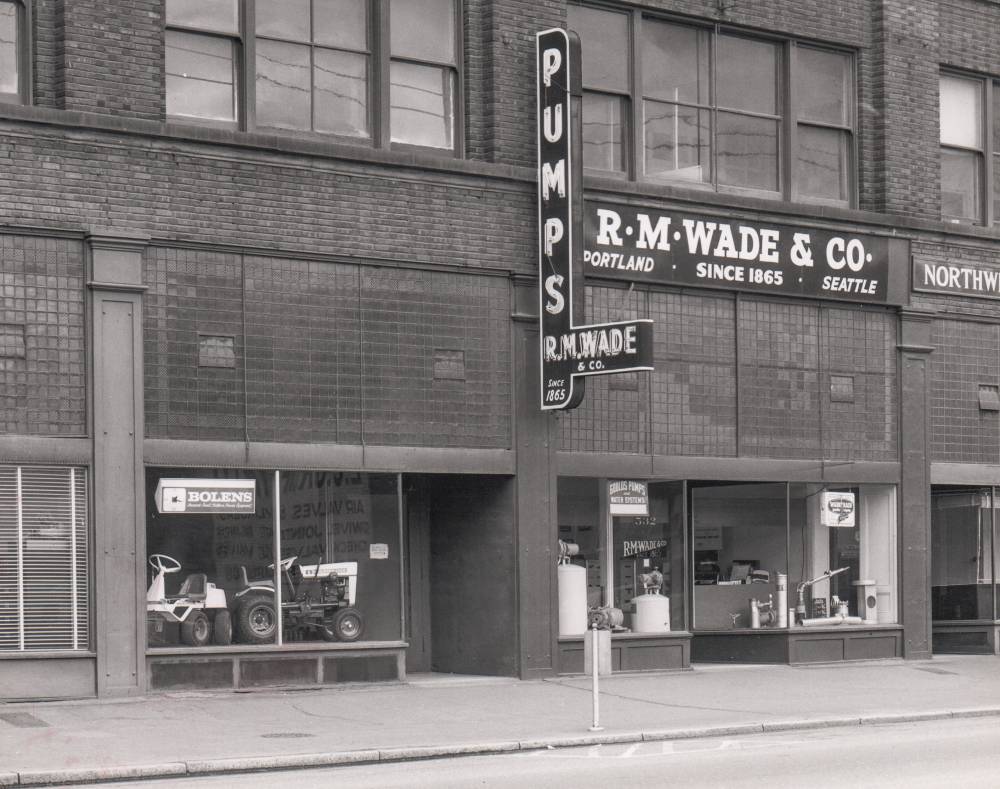

R.M. Wade - Seattle Branch

In 1964 R.M. Wade & Co. opened a branch in Seattle. Even though R.M. Wade closed most of its branches in later years, the Seattle branch continued under the leadership of Fred Pringle. It was very successful and was a big profit contributor to the company. It sold pumps, water system components, and plastic pipe and fittings.