On the 150th anniversary of the founding of R.M. Wade and Co., this website memorializes the company's history and its role in the mechanization of agricultural production in the Northwest. The company was founded in 1865 to serve farmers and it has been operated by five generations of the same family.

- Pre-1865 Crossing the Oregon Trail. Married Anne Howard. First store opened in The Dalles.

- 1865-1889 Founding of R.M. Wade & Co. Started selling farm equipment and moved to Portland.

- 1890-1914 R.M Wade retires. Wade Drag Saw Introduced. Edward J. Newbegin becomes President.

- 1915-1938 World War I. Company buys Multnomah Iron Works. Wade Newbegin becomes president. Wade Rain introduced.

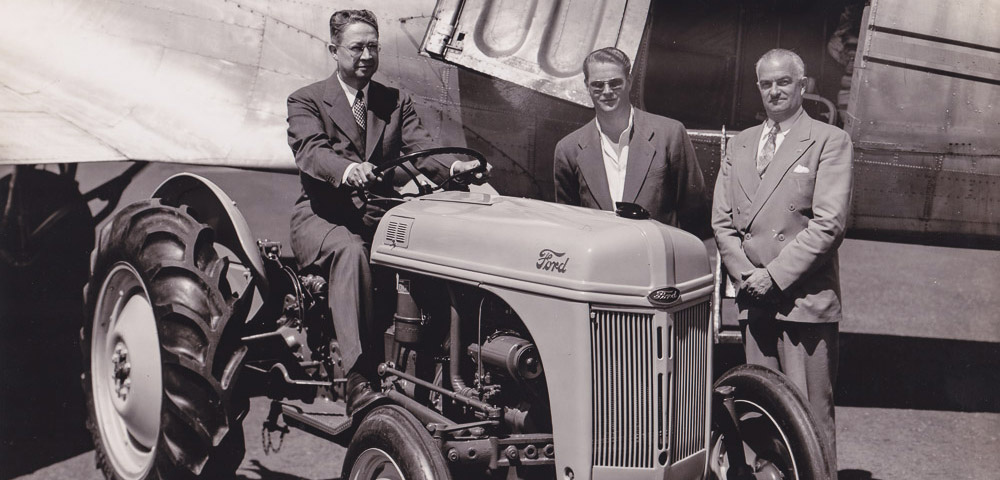

- 1939-1964 World War II. Ford Ferguson Tractor introduced. Wins “M” Award for wartime production .

- 1965-1989 Both R.M Wade and Wade Mfg. move to new locations. Wade Rain Acquires Drip Company. Ore-Max Established.

- 1990-Today Majes Project in Peru. Wade Rain of Mexico Founded. Company Divided.

- People/Contact The people of R.M. Wade & Co.